Lockout Tagout padlocks

Safety Padlocks has (Ø6mm, H38mm) hardened steel shackle, which are suitable for Industrial lockout-tagout use on conductive areas,to prevent accidental operation.

Safety Padlocks has (Ø6mm, H38mm) hardened steel shackle, which are suitable for Industrial lockout-tagout use on conductive areas,to prevent accidental operation.

Safety Padlock are divided into Steel shackle padlock, Nylon shackle padlock, Stainless steel shackle padlock,Aluminum shackle padlock and Micro small padlock, we have developed and designed each series of padlock with the function of Auto-pop function shackle , and ensure the key retaining.

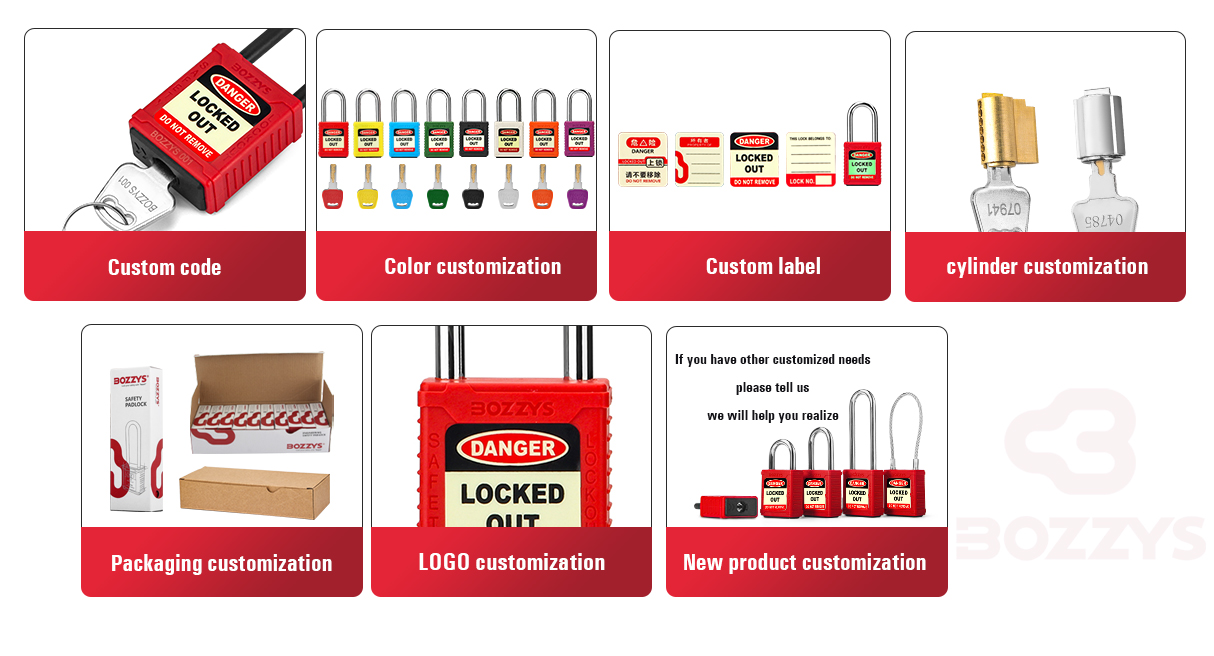

“The padlock adopts reinforced nylon one-piece injection-molded lock shell, which is resistant to temperature difference (-20°–+177°), impact resistance and corrosion resistance. There are 10 standard colors to choose from: red, yellow, blue, green, black, white, orange, purple, brown, gray. Can meet the classification of safety management. Various colors can be customized according to customer requirements.”

Padlock cylinder is made of zinc alloy , which can be made of copper, stainless steel and other materials, and the auto popup lock shackle also can be customized. Zinc alloy cylinder is 12-14 pins , it can realize that more than 100,000pcs padlocks do not open each other.Copper cylinder is 6 pins , it can realize that more than 60,000pcs padlocks do not open each other.

Key management system: Keyed differ,keyed alike,differ&master key,alike&master key.

Safety Padlock has key retaining feature,and key cannot be pulled out in open state, in order to prevent the key from being lost. The non-conductive, non-sparking shell of the padlock can protect workers from electric shock.

The key of the padlock can be customized with different color key covers, fast identification with color matched lock and key.

Comply with OSHA standard: 1 employee = 1 padlock = 1 key.

- Padlock has a label with text: “Danger locked out”/”Do not remove, property”. Label can be customized.

- The lock body and key can print same code, which is convenient for management.

- Can be engraved with customers’ logo if required.

Key management system: Keyed differ,keyed alike,differ&master key,alike&master key.

When & Where should use LOTO?

Daily maintenance, adjustment, cleaning, inspection and commissioning for equipment. Enter into the limited space, hot work, dismantling work and so on in the tower, tank, electrified body, kettle, heat exchanger, pumps and other facilities.

Operation involving high voltage. ( including the operation under the high-tension cable )

Operation require closing the safety system temporary.

Operation during maintenance and commissioning of non-processing.

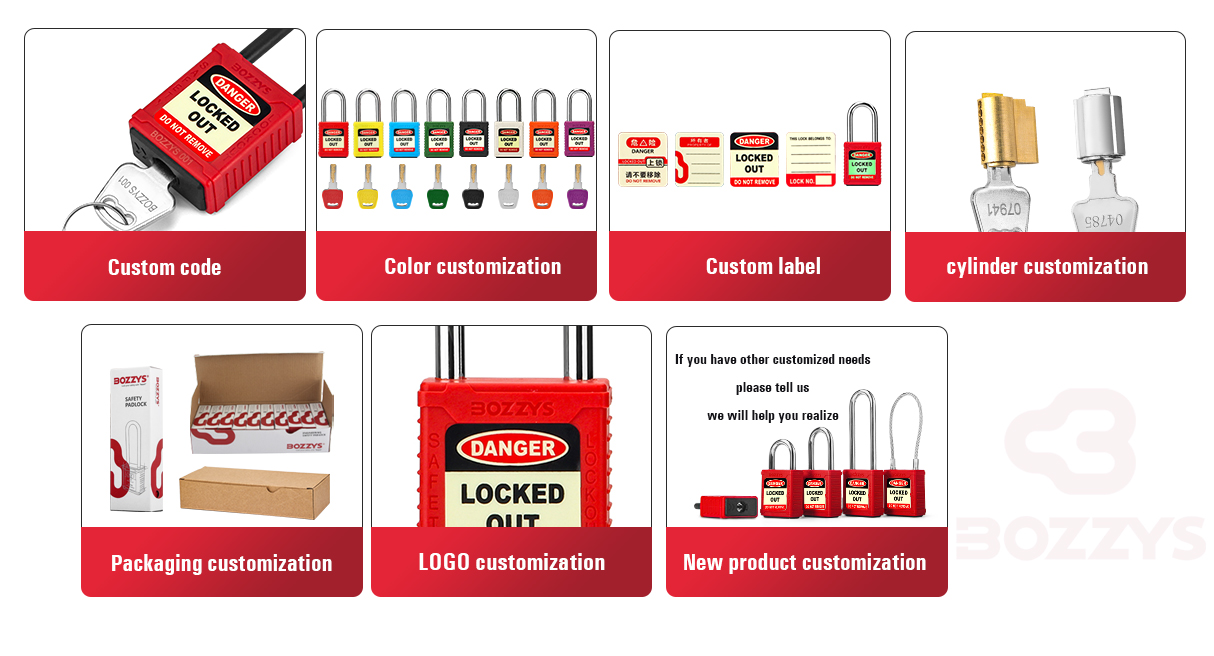

BOZZYS for you Custom exclusive lock listing program!