In the industrial sector, safety is paramount. Ball valves, a vital component in many systems, are prone to accidental activation, which can lead to dangerous situations such as leaks, exposure to hazardous substances, or system damage. To prevent these potentially harmful incidents, the Ball Valve Lockout has become an indispensable safety device in workplaces across various industries. Designed to manage and prevent the accidental activation of ball valves, this device ensures that operations remain safe, secure, and efficient.

Overview of Ball Valve Lockout

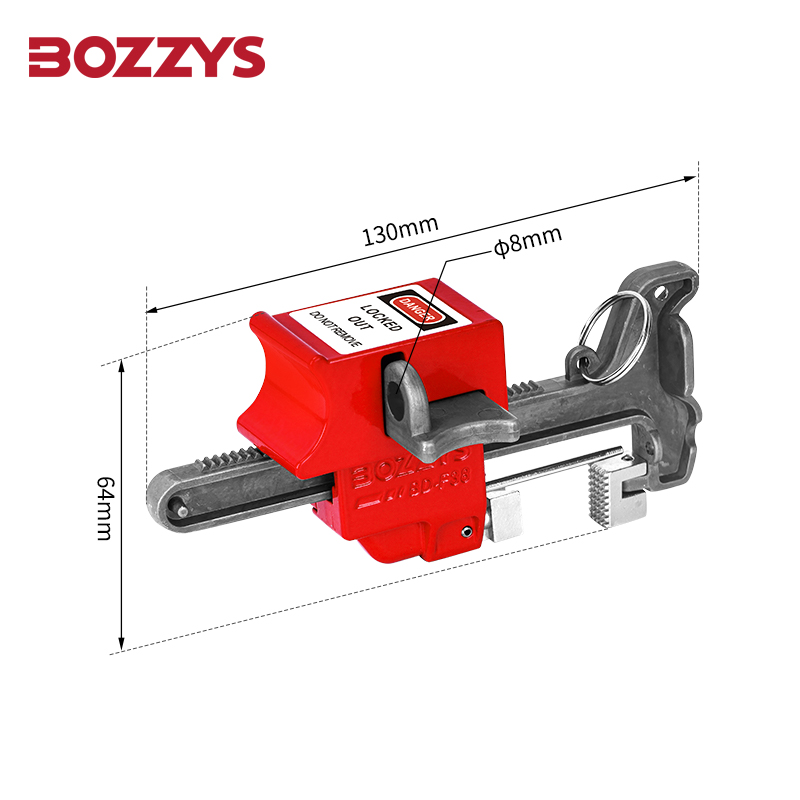

The Ball Valve Lockout is specifically designed for ball valves with diameters ranging from 1/4 inch (6 mm) to 4 inches (101 mm). It is a highly versatile tool used to secure valves of different sizes and is suitable for use in confined or insulated pipelines, making it an ideal choice for many industrial applications. The lockout is primarily used to isolate energy sources and prevent the release of hazardous materials, ensuring that valves remain in their intended position-whether open or closed-until the lockout is removed by authorized personnel.

Key Features of Ball Valve Lockout

The Ball Valve Lockout is engineered with several unique features that make it a highly effective and user-friendly safety device. Let’s explore its key characteristics:

Clamping Serration Design

One of the defining features of the Ball Valve Lockout is its clamping serration design, which makes it incredibly efficient at securing ball valves. This design includes a clamping handle stop device, which securely holds the ball valve handle in place, preventing any movement that could accidentally activate or deactivate the valve. This feature offers several advantages:

- Tool-Free Operation: The clamping serration design requires no additional tools, making the Ball Valve Lockout quick and easy to install.

- Speed and Efficiency: Workers can secure or release the valve lockout in a matter of seconds, reducing downtime and improving productivity.

- Versatility: The clamping serration design allows for the lockout of various American standard ball valves, making it a versatile solution for multiple types of valves and systems.

Closed Stem Design

Safety is the primary concern when using any lockout device, and the closed stem design of the Ball Valve Lockout addresses this need with utmost reliability. The closed stem design works by sealing off the valve’s stem, ensuring that even if the valve handle is removed, the valve cannot be accidentally reactivated.

- Enhanced Safety: This feature is particularly valuable in preventing accidents caused by tampering or accidental removal of the valve handle.

- Guaranteed Isolation: With the stem sealed, the Ball Valve Lockout guarantees that the valve remains in its current position (either open or closed) until the lockout is deliberately disengaged by authorized personnel.

- Applicable in Various Conditions: The closed stem design also allows the lockout to be used in enclosed spaces and insulated pipelines, making it a versatile solution for different work environments.

Durable Aluminum Alloy Construction

The Ball Valve Lockout is constructed from aluminum alloy, a material known for its durability, corrosion resistance, and lightweight properties. This ensures that the device can withstand harsh industrial environments, including exposure to chemicals, moisture, and extreme temperatures.

- Long-Lasting Performance: The robust aluminum alloy construction allows the lockout to endure the rigors of industrial use, providing long-lasting performance and reliability.

- Lightweight and Portable: Despite its strength, the Ball Valve Lockout remains lightweight, making it easy for workers to transport and install without adding unnecessary strain.

Easy Operation for Improved Efficiency

Ease of use is a critical factor in ensuring that safety devices are effectively employed in the workplace. The Ball Valve Lockout is designed for quick and effortless operation, allowing workers to lock and unlock valves without the need for complex tools or specialized skills.

- Quick Installation and Removal: The lockout can be installed and removed in a matter of seconds, minimizing the time required for lockout/tagout procedures.

- Self-Installation: Workers can install the lockout device themselves, following simple instructions provided by the manufacturer. This eliminates the need for external specialists and reduces downtime associated with safety procedures.

- Enhanced Productivity: By improving the efficiency of valve lockout procedures, this device contributes to overall productivity, allowing workers to focus on their tasks without the risk of accidental valve activation.

Applications of Ball Valve Lockout

The Ball Valve Lockout is suitable for a wide range of industrial applications, particularly in industries that rely on pressurized systems, such as:

- Oil and Gas: In the oil and gas industry, ball valves control the flow of volatile fluids and gases. A Ball Valve Lockout can prevent accidental leaks, spills, and other hazards.

- Chemical Processing: Chemical plants often handle hazardous materials that require careful management. The lockout device ensures that valves remain securely closed during maintenance or repair work.

- Water Treatment: In water treatment facilities, ball valves regulate the flow of water and chemicals used in treatment processes. The Ball Valve Lockout can prevent unintended releases that could disrupt operations or pose safety risks.

- Food and Beverage: Ensuring hygienic conditions in food and beverage production is essential. The Ball Valve Lockout prevents contamination by keeping valves securely in place during cleaning and maintenance.

- Manufacturing: General manufacturing processes often involve the use of liquids, gases, or steam, where ball valves play a crucial role. The lockout helps protect workers from accidental exposure to hazardous substances.

Advantages of Using a Ball Valve Lockout

Implementing the Ball Valve Lockout as part of a broader safety program offers several advantages to businesses and workers alike:

- Accident Prevention: The primary advantage of using a Ball Valve Lockout is preventing accidental valve activation, which can lead to injuries, leaks, equipment damage, and production downtime.

- Compliance with Safety Standards: Lockout/tagout procedures are required by occupational safety regulations such as OSHA (Occupational Safety and Health Administration). By using a Ball Valve Lockout, companies ensure they are in compliance with these safety standards, avoiding penalties and improving workplace safety.

- Improved Maintenance Efficiency: With the ability to quickly secure and release ball valves, the lockout device streamlines maintenance and repair procedures, reducing downtime and improving operational efficiency.

- Enhanced Worker Safety: Ensuring that valves remain securely in place during maintenance protects workers from hazardous releases, leaks, and accidental exposure to dangerous materials.

The Ball Valve Lockout is an essential safety device for industries that rely on ball valves to control the flow of fluids, gases, or other substances. With its durable construction, easy operation, and innovative features like the clamping serration design and closed stem design, the Ball Valve Lockout provides a reliable solution for preventing accidental valve activation.

By incorporating Ball Valve Lockouts into safety protocols, companies can protect workers, maintain compliance with safety regulations, and improve the efficiency of their maintenance processes. Whether in oil and gas, chemical processing, water treatment, or other industries, this device plays a vital role in ensuring that operations remain safe, secure, and productive.

2

2