A butterfly valve lockout is a critical safety device used in industrial settings to prevent accidental or unauthorized operation of butterfly valves. These valves control the flow of fluids or gases through pipelines and are commonly found in various industries including oil and gas, chemical processing, and manufacturing. The lockout device ensures that valves remain in their intended position, reducing the risk of hazardous spills, equipment damage, and personal injury.

Components and Construction

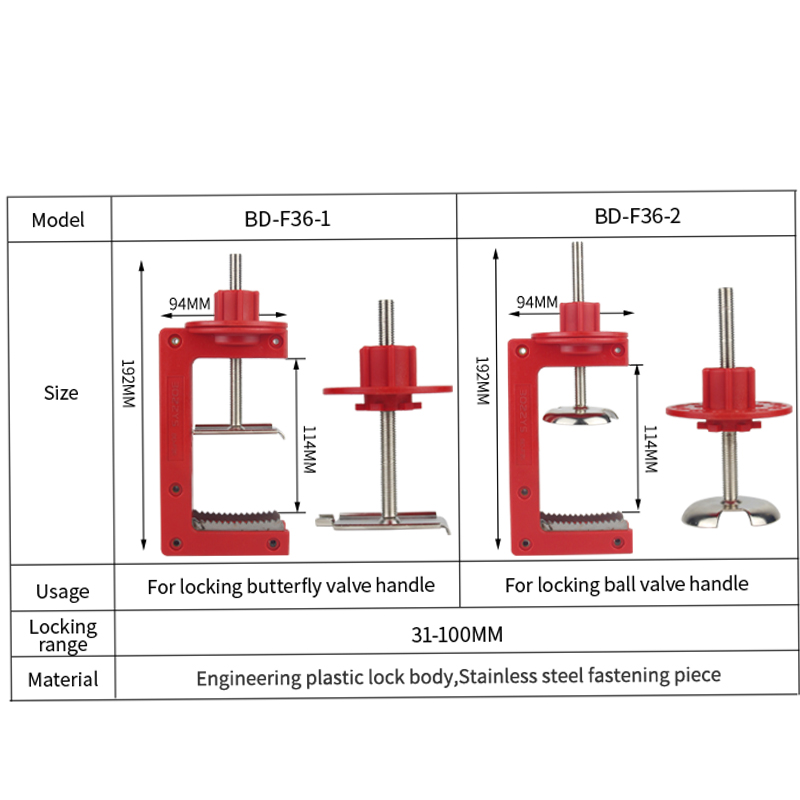

The butterfly valve lockout device, such as the F36 series, is meticulously designed with robust materials to withstand demanding industrial environments:

Lock Body

Constructed from high-strength engineering plastic PC, the lock body of the F36 series offers exceptional durability and resistance to chemical corrosion. This material choice ensures longevity and reliability, even in harsh conditions where exposure to chemicals or extreme temperatures is common.

Compression Blocks

The F36 series includes specialized compression blocks designed for different valve types:

- Bar-shaped Compression Block (F36-1): This block is specifically tailored for butterfly valves, providing a secure fit over the valve handle. It effectively immobilizes the valve, preventing accidental operation and ensuring operational safety.

- Round Compression Block (F36-2): Designed for ball valves, this round block securely locks the valve handle in place, preventing unintended activation and potential hazards.

Screws and Fasteners

Equipped with toothed carbon steel and stainless steel screws, the butterfly valve lockout ensures a firm and reliable grip on valve handles. The stainless steel sawtooth design enhances security by preventing loosening due to vibrations or external forces.

Locking Mechanism

Featuring integrated locking screws, the device allows for tool-free operation during application and removal. This user-friendly design simplifies maintenance procedures and facilitates quick implementation of lockout/tagout (LOTO) protocols.

Visibility and Labelling

Butterfly valve lockouts are often designed in bright colours, enhancing visibility in industrial settings. Clear labelling and identification markings further aid in quick recognition, ensuring compliance with safety protocols and facilitating efficient maintenance operations.

Weather Resistance

Designed to withstand diverse environmental conditions, including exposure to UV radiation and extreme temperatures, the lockout device maintains its performance integrity over time. This weather-resistant construction ensures reliability in outdoor and indoor industrial environments alike.

Key Features

Understanding the key features of butterfly valve lockouts is essential for ensuring effective industrial safety and operational efficiency. These specialized devices are designed to securely immobilize butterfly valves, preventing accidental or unauthorized operation that could lead to hazardous incidents or operational disruptions. From robust construction materials to intuitive locking mechanisms, each feature serves a crucial role in safeguarding personnel, equipment, and the environment. This article explores the essential features of butterfly valve lockouts, highlighting their importance in promoting workplace safety, regulatory compliance, and cost-effective maintenance practices.

- Locking Mechanism: The F36 series features a bar-shaped compression block (F36-1) designed specifically for butterfly valves. This block securely clamps onto the valve handle, effectively immobilizing it to prevent accidental or unauthorized operation.

- Versatility: Additionally, the F36 series includes a round compression block (F36-2) suitable for ball valves. This block ensures that ball valve handles remain locked in place, preventing unintended valve activation.

- Secure Fastening: The stainless steel sawtooth design ensures a tight grip on valve handles, minimizing the risk of loosening due to vibrations or external forces.

- Multi-Lock Capability: Multiple padlocks can be applied to the device simultaneously, allowing authorized personnel to lock out the equipment securely. This feature supports effective lockout/tagout (LOTO) procedures, essential for compliance with safety regulations.

- Tool-Free Operation: With locking screws integrated into the design, the butterfly valve lockout can be applied and removed without the need for additional tools, simplifying maintenance procedures.

- Visible Identification: Butterfly valve lockouts are often equipped with bright colours and labels for clear visibility. This visual identification helps operators and maintenance personnel quickly identify locked-out valves, enhancing safety protocols and operational efficiency.

- Durability and Weather Resistance: Constructed from high-quality materials such as engineering plastic and stainless steel, butterfly valve lockouts withstand harsh industrial environments, including exposure to chemicals, UV radiation, and extreme temperatures. This durability ensures long-term reliability and performance.

- User-Friendly Design: Designed with user convenience in mind, butterfly valve lockouts feature ergonomic shapes and intuitive locking mechanisms. This user-friendly design facilitates quick and effective application, supporting efficient maintenance practices and minimizing downtime.

Application and Benefits

Butterfly valve lockouts are indispensable tools for industrial safety management. By effectively securing valve handles, these devices:

- Enhanced Safety: Butterfly valve lockouts play a crucial role in enhancing workplace safety by preventing unauthorized operation of critical valves. This ensures that only authorized personnel can access and modify valve settings, reducing the risk of accidents and injuries due to unintended release of hazardous materials.

- Compliance with Regulations: In industries subject to stringent safety regulations, such as oil and gas or chemical processing, the use of butterfly valve lockouts is essential for complying with standards like OSHA’s lockout/tagout (LOTO) requirements. These regulations mandate the isolation of energy sources to prevent unexpected start-up of machinery or equipment, mitigating potential hazards.

- Operational Efficiency: By implementing effective lockout procedures using butterfly valve lockouts, organizations can minimize downtime caused by accidents or equipment damage. This proactive approach helps maintain continuous operations and optimizes productivity, contributing to overall operational efficiency.

- Cost Savings: The financial benefits of using butterfly valve lockouts extend beyond operational efficiency. By preventing accidents and minimizing equipment damage, businesses can reduce costs associated with repairs, downtime, and insurance premiums. This proactive safety measure ultimately leads to significant long-term savings and improved profitability.

- Environmental Protection: Properly secured butterfly valves prevent the release of hazardous substances into the environment, mitigating potential environmental impacts and ensuring compliance with environmental regulations. This demonstrates corporate responsibility and commitment to sustainability practices.

In conclusion, investing in butterfly valve lockout devices like the F36 series is crucial for maintaining workplace safety in industrial environments. These robust and versatile tools not only prevent accidents but also contribute to operational efficiency and regulatory compliance. By equipping employees with the right lockout tools and safety devices, businesses can protect lives, reduce costs, and ensure smooth operations.

2

2