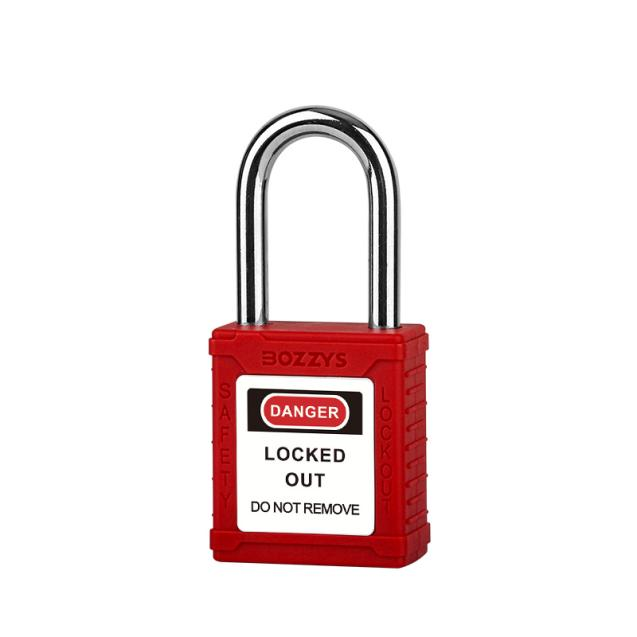

Padlocks are essential safety devices used in various industrial and commercial settings to prevent accidental or unauthorized access to machinery, equipment, or restricted areas. They play a crucial role in lockout/tagout (LOTO) procedures, which are designed to ensure the safety of workers during maintenance, repair, or cleaning operations. Padlocks come in different materials, such as steel, nylon, stainless steel, and aluminum, each with its own unique properties and applications. Safety padlocks are specifically designed to meet industry standards and regulations, featuring features like hardened steel shackles, non-conductive bodies, and key-retaining mechanisms. These padlocks are available in various colors, which can be used for visual identification and safety management purposes. With customizable options like engraving, key systems, and labeling, padlocks can be tailored to meet specific operational requirements, ensuring a secure and safe working environment.

Features of Nylon Padlocks

Nylon padlocks are designed with several key features that make them a popular choice for various applications. Here are notable features of nylon padlocks:

Non-Conductive Body

Nylon padlocks feature a non-conductive body, which means the material used to construct the padlock's body does not allow the flow of electricity. This feature is crucial in environments where there is a risk of electric shock or sparks, such as power plants, construction sites, or any place with exposed electrical wiring or equipment. By using a non-conductive material like nylon, these padlocks eliminate the potential for electric current to pass through the padlock, ensuring the safety of workers handling them. This non-conductive property also prevents the padlock from becoming a conductor in the event of an electrical fault, further enhancing its safety profile.

Corrosion Resistance

One of the key advantages of nylon padlocks is their excellent resistance to corrosion. Unlike metal padlocks, which can rust or corrode over time due to exposure to moisture, chemicals, or harsh environmental conditions, nylon padlocks maintain their structural integrity and functionality. The nylon material used in their construction is highly resistant to corrosive agents, making these padlocks suitable for use in outdoor environments, coastal areas, or industrial settings where corrosive substances are present. This corrosion resistance ensures that the padlocks remain functional and reliable, even in challenging conditions, reducing the need for frequent replacement and maintenance.

Impact Resistance

Nylon is known for its durability and ability to withstand impact and shock. Nylon padlocks are designed to be highly resistant to impact, making them less likely to crack or break when dropped or subjected to rough handling. This impact resistance is particularly beneficial in industrial settings or construction sites, where padlocks may be exposed to accidental impacts or harsh conditions. Unlike metal padlocks, which can dent or deform upon impact, nylon padlocks maintain their shape and functionality, ensuring continued security and reliability.

Lightweight Construction

One of the standout features of nylon padlocks is their lightweight construction. Compared to metal padlocks, which can be quite heavy, nylon padlocks are significantly lighter in weight. This lightweight nature makes them easier to carry and transport, reducing the physical strain on workers who need to move or handle multiple padlocks throughout the workday. The reduced weight also minimizes the risk of injuries associated with lifting or carrying heavy objects, making nylon padlocks a more ergonomic choice for various applications.

Customizable Colors

Nylon padlocks are available in a wide range of colors, which can be used for visual identification and safety management purposes. Different colors can be assigned to different departments, employees, or levels of access, creating a color-coding system that makes it easier to identify and manage the padlocks used in a facility. For example, red padlocks could be used for high-risk areas, while blue padlocks could be assigned to maintenance personnel. This color customization not only enhances security protocols but also improves overall safety by providing a clear visual cue for different access levels or areas.

Conclusion

Nylon padlocks offer a unique combination of features that make them an attractive choice for various applications. Their non-conductive properties, corrosion resistance, impact resistance, lightweight construction, and customizable colors contribute to enhancing safety, durability, and ease of use. These padlocks are particularly well-suited for industrial settings, construction sites, and environments with electrical hazards or harsh conditions. By prioritizing worker safety, operational efficiency, and effective security management, nylon padlocks have become a popular and practical solution for a wide range of industries and organizations. Their versatility and reliable performance make them a valuable investment for any business or facility prioritizing safety and security.

2

2