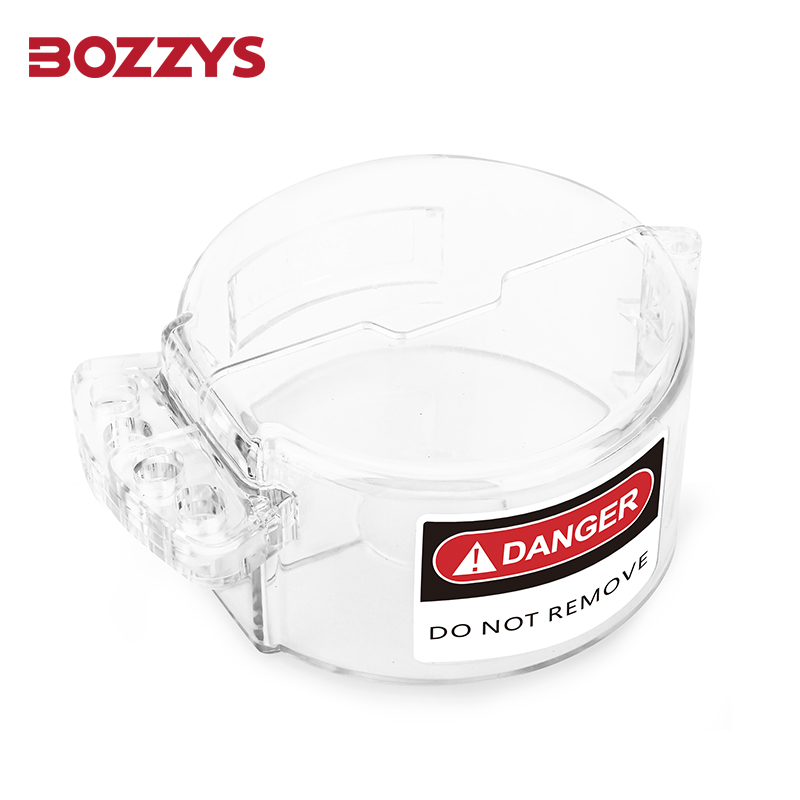

The Transparent Butterfly Handle Ball Valve Lockout is a crucial safety device designed to prevent unauthorized operation of butterfly handle ball valves in industrial settings. This lockout device is specifically crafted to fit valves ranging from 1/4 inch to 1 inch in size, making it versatile for various applications. Made from high-strength, transparent PC material, it offers excellent durability and resistance to impact, extreme temperatures (-40°C to 130°C), and oxidation. This makes it suitable for use in harsh operating environments. The device is user-friendly, requiring no tools for installation, and can be easily secured with a safety padlock and lockout tag. Its transparent design allows for visual confirmation of the valve’s position, enhancing safety protocols. The lockout comes with customizable safety labels that can be easily applied and removed, supporting multiple languages to cater to diverse workforces. Additionally, the device can be personalized with custom logos through various methods such as laser engraving or pad printing. By effectively preventing accidental valve operation, this lockout device plays a vital role in ensuring employee safety and maintaining operational integrity in industrial environments where valve control is critical.

Features of the Transparent Butterfly Handle Ball Valve Lockout

Transparent Design

The lockout device is made from clear, see-through material. This transparency is a key feature because it allows workers to easily see the position of the valve handle without removing the lockout. In many industrial settings, it’s crucial to know if a valve is open or closed at a glance. The transparent design makes visual inspections quick and easy, improving overall safety and efficiency. Workers can confirm the valve’s status without touching or manipulating the lockout, which is especially important in potentially hazardous environments. This feature also helps during audits or inspections, as supervisors can quickly verify that valves are in their correct positions without interfering with the lockout. The clear material also allows for easy identification of any damage or wear to the lockout device itself, ensuring that it’s always in good working condition. In emergency situations, this visibility can be critical, allowing rapid assessment of valve positions without the need to remove or manipulate the lockout. Overall, the transparent design enhances safety, speeds up inspections, and contributes to more efficient operations in industrial settings where valve control is crucial.

Size Compatibility

This lockout device is designed to fit butterfly handle ball valves ranging from 1/4 inch to 1 inch in size. This wide range of compatibility is a significant advantage because it means that a single type of lockout can be used for multiple valve sizes in a facility. This reduces the need for different lockout types, simplifying inventory management and training processes. Workers only need to be familiar with one device for various valve sizes, which can lead to more consistent and effective lockout procedures. The versatility of this size range makes the lockout suitable for use in diverse industrial applications, from small-scale operations to larger manufacturing plants. It also reduces the chances of using the wrong size lockout, which could compromise safety. For maintenance teams that work across different areas or facilities, having a single lockout that fits multiple valve sizes means they can carry fewer tools, making their job easier and more efficient. This size compatibility also makes it easier for companies to standardize their safety procedures across different departments or locations, ensuring consistent safety practices throughout their operations.

Durable PC Material Construction

The lockout is constructed from PC (polycarbonate) material, known for its high strength and durability. This choice of material offers several benefits that make it ideal for industrial use. Firstly, PC is highly impact-resistant, meaning the lockout can withstand accidental drops or collisions without breaking or cracking. This durability ensures that the lockout remains effective even in rough industrial environments. Secondly, the material can withstand a wide temperature range from -40°C to 130°C, making it suitable for use in various environments, from freezing cold storage areas to hot manufacturing floors. Additionally, PC material resists oxidation, which means it won’t rust or corrode when exposed to air or moisture. This property extends the life of the lockout and ensures it remains functional even in humid or wet conditions. While not explicitly mentioned, PC generally has good resistance to many chemicals, making it suitable for use in various industrial settings where exposure to different substances is possible. The combination of these properties ensures that the lockout device remains effective and maintains its integrity over time, even under harsh conditions. This durability translates to longer service life, reduced replacement costs, and consistent safety performance in challenging industrial environments.

Easy Installation

The lockout device is designed for easy installation, requiring no tools. This feature is crucial for several reasons that contribute to improved safety and efficiency in industrial settings. Firstly, the quick installation means less downtime during maintenance or emergency shutdowns. Workers can rapidly secure valves without searching for specific tools, which is particularly important in time-sensitive situations. Secondly, tool-free installation makes the lockout accessible to all authorized personnel, regardless of whether they have access to a toolbox. This universal accessibility ensures that safety procedures can be followed by anyone who needs to lock out a valve. The simple installation process also reduces the chance of errors. Workers are more likely to use the lockout correctly when the process is straightforward, which is essential for maintaining a safe working environment. Additionally, easy installation allows for quick removal and reapplication if needed, making the lockout adaptable to changing situations or emergency responses. The lockout can be opened, placed over the valve handle, and then closed and secured with a padlock in a matter of seconds. This simplicity ensures that even in stressful situations or emergencies, workers can quickly and effectively lock out the valve, minimizing risks and potential hazards.

Safety Padlock Compatibility

The lockout device is designed to be secured with a safety padlock, a feature that is essential for ensuring effective lockout/tagout procedures. This compatibility allows each worker to use their own padlock, ensuring that only they can remove the lockout. This personal accountability is a cornerstone of many lockout/tagout programs and significantly enhances safety by preventing unauthorized valve operation. The ability to use multiple padlocks also supports group lockout scenarios, where several workers or teams need to secure a single valve. This is particularly important in complex maintenance operations where multiple trades or departments may be working on interconnected systems. The padlock compatibility also allows for the use of standardized safety padlocks, which can be color-coded or keyed specifically for certain individuals or departments. This can help in quickly identifying who has locked out a particular valve and for what purpose. Additionally, the use of padlocks provides a physical and visual deterrent against tampering or accidental operation of the valve. The presence of a locked padlock serves as a clear indication that the valve is under a lockout procedure and should not be operated. This visual cue can be crucial in preventing accidents in busy industrial environments where multiple activities may be occurring simultaneously.

Customizable Safety Labels

The butterfly handle ball valve lockout devices come with prominent safety labels that can be customized to suit specific needs. This feature is crucial for clear communication and proper identification in industrial settings. The labels can be easily affixed to the lockout device, providing important information such as the responsible person’s name, the reason for the lockout, or specific safety instructions. What makes this feature particularly useful is its flexibility – the label content can be customized to include different languages, making it accessible to diverse workforces in multinational companies or areas with multilingual staff. This ensures that safety information is understood by all workers, regardless of their native language. The labels are designed to be easily removed after each task, allowing for quick updates or changes for the next lockout procedure. This reusability makes the lockout device more versatile and cost-effective. The ability to customize labels also allows companies to include specific company protocols or emergency contact information, further enhancing safety measures. By providing clear, visible, and customizable information, these labels play a crucial role in maintaining safety standards and ensuring that all workers are aware of the lockout status and relevant details.

Logo Customization Options

The lockout device offers various options for logo customization, which can be beneficial for companies in several ways. Logos can be added through laser engraving, pad printing, or molding, allowing for permanent and professional-looking branding. This feature enables companies to easily identify their equipment, which is particularly useful in settings where multiple contractors or companies might be working together. Branded lockouts can help prevent mix-ups or loss of equipment. Additionally, custom logos can include company-specific safety messages or instructions, reinforcing safety protocols every time a worker uses the device. For large organizations, different departments or units can have their own branded lockouts, making it easier to track and manage equipment across various locations. The ability to add logos also allows for the inclusion of important information like serial numbers or asset tags, which can be crucial for inventory management and equipment tracking. From a psychological perspective, branded safety equipment can foster a sense of ownership and responsibility among workers, potentially leading to more diligent adherence to safety procedures. This customization option demonstrates the manufacturer’s understanding of corporate needs beyond just functionality, offering a product that serves both safety and branding purposes.

Resistance to Deformation

The Transparent Butterfly Handle Ball Valve Lockout is designed to be resistant to deformation, which is a crucial feature for maintaining its effectiveness over time. This resistance to deformation means that the lockout device retains its shape and functionality even when subjected to various stresses in industrial environments. For instance, if the lockout is accidentally stepped on or if heavy equipment brushes against it, it’s less likely to bend or break. This durability ensures that the lockout continues to fit properly on the valve handle and provides consistent protection against unauthorized operation. The resistance to deformation also contributes to the longevity of the device, reducing the frequency of replacements and thereby lowering long-term costs for the company. In environments with extreme temperatures or in outdoor settings where the device might be exposed to sunlight or other weather conditions, this feature helps prevent warping or weakening of the material. This stability is essential for maintaining a secure fit on the valve handle, as a deformed lockout might not properly prevent valve operation. The resistance to deformation also helps maintain the clarity of the transparent material, ensuring that the valve position remains visible over time. This feature demonstrates the manufacturer’s consideration of long-term use in challenging industrial conditions, providing a reliable safety solution that maintains its integrity and effectiveness.

Suitable for Harsh Operating Environments

The Transparent Butterfly Handle Ball Valve Lockout is specifically designed to withstand harsh operating environments, making it a versatile and reliable choice for various industrial settings. This suitability for tough conditions is due to a combination of its material properties and design features. The device can endure extreme temperatures, from freezing cold to intense heat, without losing its structural integrity or functionality. This temperature resistance makes it suitable for use in outdoor facilities, cold storage areas, or near heat-generating equipment. The lockout’s resistance to oxidation means it can be used in humid or corrosive environments without rusting or degrading, which is particularly important in chemical plants, marine environments, or food processing facilities where moisture and corrosive substances are common. Its impact-resistant nature allows it to withstand accidental collisions or drops, which are not uncommon in busy industrial settings with moving machinery or equipment. The device’s ability to resist deformation ensures it maintains its protective function even under physical stress. This durability in harsh conditions means that the lockout device remains effective and reliable over time, reducing the need for frequent replacements and ensuring consistent safety performance. By being able to withstand these challenging environments, the lockout device provides a dependable safety solution across a wide range of industries and applications, from oil and gas facilities to manufacturing plants and beyond.

Effortless Operation

The Transparent Butterfly Handle Ball Valve Lockout is designed for effortless operation, a feature that significantly enhances its usability and effectiveness in industrial settings. The ease of use starts with its tool-free installation process, allowing workers to quickly and easily secure the lockout device to the valve handle. This simplicity is crucial in emergency situations or during routine maintenance when time is of the essence. The lockout can be opened, placed over the valve handle, and secured in a matter of seconds, requiring minimal physical effort. This effortless operation reduces the likelihood of worker fatigue or repetitive strain injuries that could occur with more cumbersome lockout devices, especially in environments where multiple lockouts need to be applied regularly. The straightforward design also minimizes the potential for user error, ensuring that the lockout is correctly applied every time. The simplicity of operation makes it easier for new employees to learn and apply proper lockout procedures, potentially reducing training time and improving overall safety compliance. Additionally, the effortless operation encourages more frequent and consistent use of the lockout device, as workers are less likely to skip or rush through safety procedures when they are quick and easy to perform. This user-friendly design demonstrates a thoughtful approach to safety equipment, recognizing that the easier a safety device is to use, the more likely it is to be used correctly and consistently, thereby enhancing overall workplace safety.

Conclusion

The Transparent Butterfly Handle Ball Valve Lockout is a crucial safety device for industrial settings. Its transparent design, size compatibility, and durable construction make it versatile and reliable. The device’s easy installation, customizable labels, and logo options enhance its usability and identification. Its resistance to harsh environments and deformation ensures long-lasting performance. The effortless operation encourages consistent use, improving overall safety. With features like padlock compatibility and suitability for various valve sizes, this lockout device offers a comprehensive solution for preventing unauthorized valve operation. By combining practicality, durability, and user-friendly design, it significantly contributes to maintaining a safe work environment across various industries, making it an essential tool for any safety-conscious operation.

2

2