In the realm of industrial safety and security, the need for robust, reliable, and tamper-resistant locking mechanisms cannot be overstated. Among the myriad of locking solutions available, the heavy-duty pry-proof lockout hasp stands out as a paragon of durability and functionality. With a jaw clearance of 27mm, this hasp is designed to meet the stringent demands of various industries, ensuring that equipment remains inoperative until authorized personnel have completed their tasks. This article delves into the intricacies of the heavy-duty pry-proof lockout hasp, highlighting its construction, features, applications, and the benefits it brings to industrial safety protocols.

Constructed for Durability: The Role of 304 Stainless Steel

At the heart of the heavy-duty pry-proof lockout hasp is its construction from 304 stainless steel. This material is renowned for its corrosion resistance and rust-proof properties, making it an ideal choice for applications where exposure to harsh environmental conditions is inevitable. The use of 304 stainless steel ensures that the hasp maintains its structural integrity over time, withstanding the rigors of daily use and exposure to corrosive elements. This material's durability is a testament to the hasp's ability to perform reliably in even the most challenging environments.

Isolation Lock Points: Security and Usability in Harmony

One of the defining features of the heavy-duty pry-proof lockout hasp is its isolation lock points. These points are designed to be both easy to use and highly secure. The simplicity of their design ensures that they are readily accepted by workers, who can quickly and efficiently lock and unlock the hasp as needed. At the same time, the lock points are engineered to resist picking, making them a formidable barrier against unauthorized access. This balance of usability and security is crucial in maintaining the integrity of safety protocols and preventing unauthorized access to equipment.

Multiple Operator Lockout: Facilitating Teamwork and Safety

In many industrial settings, multiple workers may need to access and lock out equipment simultaneously. The heavy-duty pry-proof lockout hasp excels in such scenarios, allowing for lockout by multiple operators at a single lockout point. This feature ensures that equipment remains inoperative until all padlocks have been removed, preventing premature activation and potential accidents. By facilitating teamwork and coordination among workers, the hasp contributes to a safer and more efficient work environment.

Equipment Inoperability: Ensuring Safety During Repairs and Adjustments

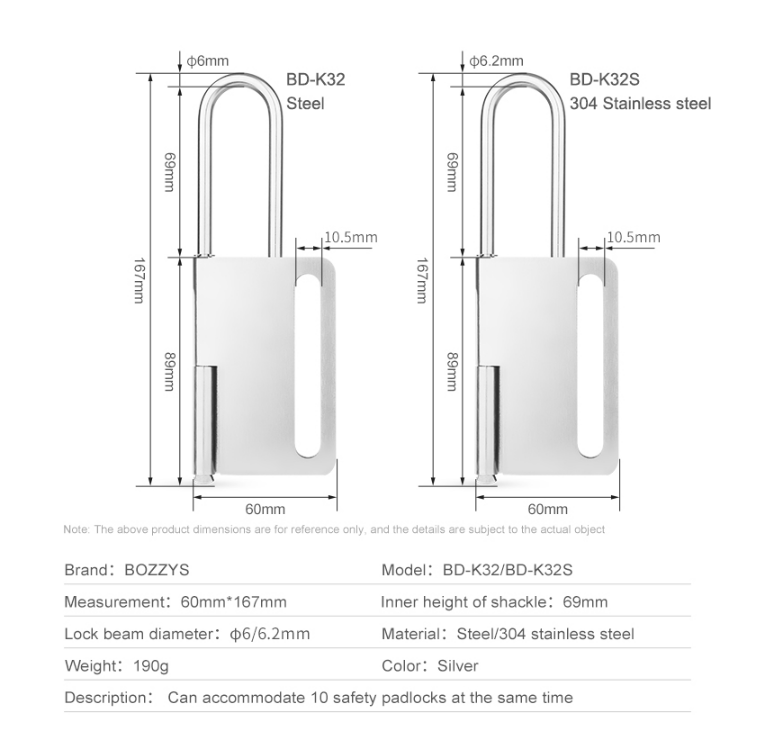

When equipment needs to be repaired or adjusted, it is imperative that it remains inoperative to prevent accidents. The heavy-duty pry-proof lockout hasp fulfills this role admirably. With its ability to accept padlocks with shackle diameters of up to 6.2mm, the hasp can securely hold multiple padlocks, ensuring that the equipment remains locked out until all workers have completed their tasks. This feature is particularly critical in environments where the consequences of equipment malfunction or premature activation could be severe.

Dimensions and Capacity: Meeting the Needs of Various Applications

The heavy-duty pry-proof lockout hasp boasts impressive dimensions and capacity, making it suitable for a wide range of applications. With a width of 60mm and a height of 167mm, the hasp is designed to fit securely onto a variety of equipment and structures. Inside, its jaw dimensions of 70.5mm in height provide ample space for up to 10 safety padlocks. This capacity ensures that even in situations where multiple workers need to lock out equipment, there is sufficient space for everyone's padlocks.

Laser Printing Logo: Customization for Professionalism and Branding

Beyond its functional attributes, the heavy-duty pry-proof lockout hasp offers customization options that cater to the needs of professional organizations. With laser printing capabilities, companies can engrave their logos or product information onto the hasp using a professional marking machine. This customization not only adds a touch of professionalism but also allows for branding and identification, making it easier to track and manage equipment in large industrial settings.

Applications Across Industries: Versatility in Action

The versatility of the heavy-duty pry-proof lockout hasp makes it an indispensable tool in various industries. In manufacturing, it ensures that machinery remains locked out during maintenance and repairs, preventing accidents and downtime. In the energy sector, it plays a crucial role in locking out electrical panels and other critical equipment during inspections and upgrades. Similarly, in construction, the hasp helps secure heavy machinery and tools, preventing theft and unauthorized use. Its wide range of applications underscores the hasp's ability to adapt to the unique needs of different industries.

Case Study: Enhancing Safety in a Manufacturing Facility

To illustrate the practical benefits of the heavy-duty pry-proof lockout hasp, consider a case study from a manufacturing facility. Prior to adopting the hasp, the facility faced challenges with unauthorized access to machinery and equipment during maintenance periods. This led to several accidents and instances of equipment being prematurely activated, causing damage and downtime.

Upon implementing the heavy-duty pry-proof lockout hasp, the facility noticed a significant improvement in safety protocols. Workers were able to securely lock out machinery using multiple padlocks, ensuring that equipment remained inoperative until all repairs and adjustments were completed. The hasp's durability and tamper-resistant design provided an additional layer of security, preventing unauthorized access and reducing the risk of accidents.

Moreover, the facility appreciated the hasp's customization options. By engraving their logo onto the hasp, they were able to easily identify and track equipment, enhancing their overall asset management practices. The hasp's ability to adapt to the facility's specific needs underscored its versatility and value as a safety tool.

The Heavy-Duty Pry-Proof Lockout Hasp as a Cornerstone of Industrial Safety

In conclusion, the heavy-duty pry-proof lockout hasp with 27mm jaw clearance is a cornerstone of industrial safety and security. Its construction from 304 stainless steel ensures durability and resistance to corrosion, while its isolation lock points provide a balance of usability and security. The hasp's ability to facilitate multiple operator lockout and keep equipment inoperative until all padlocks are removed makes it an invaluable tool in maintaining safety protocols.

Furthermore, its impressive dimensions and capacity, combined with customization options such as laser printing, make it suitable for a wide range of applications across various industries. The case study from a manufacturing facility demonstrates the practical benefits of the hasp in enhancing safety and reducing the risk of accidents.

In an era where industrial safety is paramount, the heavy-duty pry-proof lockout hasp stands out as a reliable and effective solution. Its robust design, versatile applications, and commitment to safety make it an indispensable tool for organizations seeking to protect their workers, equipment, and assets. As industries continue to evolve and face new challenges, the heavy-duty pry-proof lockout hasp will remain a cornerstone of industrial safety, ensuring that safety protocols are upheld and accidents are prevented.

2

2