Workplace safety is of utmost priority in any organization, especially regarding equipment and electrical equipment. Lockout/tagout (LOTO) procedures are meant to avoid sudden machine start-up while carrying out maintenance. The most appropriate cable lockout device for such procedures is the cable lockout with brass cylinder locking. The product provides added security in the workplace by limiting access, hence safeguarding workers from possible hazards.

Understanding Cable Lockouts with Brass Cylinder Locking

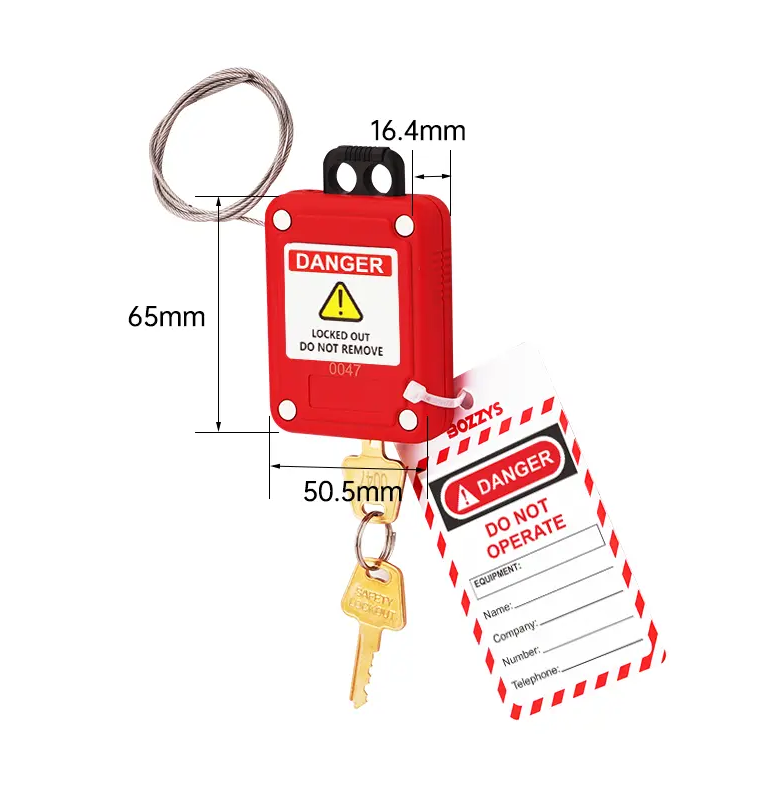

Brass cylinder locking cable lockout is an extremely tough safety device to bar access to hazardous equipment. It is 0.5-meter stainless steel cable, UV-stable PVC-coated for abusive applications. The lock is still housed in impact-resistant non-conductive PA66 nylon for industrial applications.

Once locked, the cable can be kept secure but not opened and thus is tamper-proof and very reliable. The product also includes high-visibility warning tags that can be customized with different languages, designs, and company logos, thereby enhancing safety compliance.

Special Features of Brass Cylinder Locking Cable Lockouts

Special features are:

- Long Lasting Design: Stainless steel cable with UV-resistant PVC coating ensures long-lasting use.

- Adjustable Cabled Lengths: 0.5-meter standard cable adjustable to meet security needs.

- Small Size: Compact and light for convenience of storage with equipment.

- Tamper-Resistant Locking: Brass cylinder locking system for added convenience and security.

- Warning Safety Markings: Supports multiple languages and branding for added compliance.

Industries Which Can Benefit from Cable Lockouts

Brass cylinder cable lockout is utilized widely in various industries to lockout equipment and prevent unauthorized operation. A few of the industries that utilize them are:

- Manufacturing Plants: Prevents unintended machine startups while repairing.

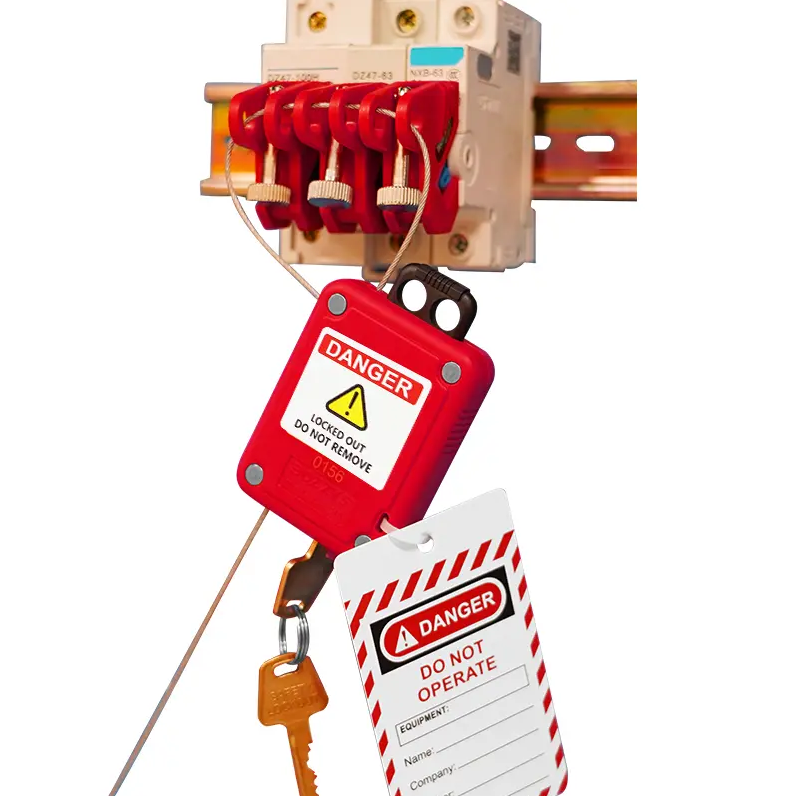

- Electric and Utility Companies: Locks high-voltage machines and cabinets out of unauthorized use.

- Warehouses and Storage Facilities: The procedures for Warehouses and Storage Facilities consist of locking out hazardous equipment together with off-limits areas.

- Building Construction Sites: Heavy machinery utilization remains prohibited through installation on building construction site entrances.

- Chemical and Pharmaceutical Plants: This protective measure applies to chemical and pharmaceutical plants where it stops dangerous chemicals and processing equipment from getting into the wrong hands.

With the implementation of these lockout devices as part of their safety protocol, companies can better reduce workplace accidents and industry standards compliance.

Why You Need a Cable Lockout with Brass Cylinder Locking

Industrial mishaps cause critical damage, loss of financial capital, and production loss. Brass cylinder locking cable lockout is an essential tool in the prevention of unauthorized operation of dangerous equipment as well as the reduction of danger.

Use of this device prevents work-place safety regulation violation, thus preventing legal liability as well as prolonged shutdowns. It also improves efficiency in operations since the maintenance crew can carry out their work without the possibility of accidental machine start-up.

Safe Use of a Cable Lockout with Brass Cylinder Locking

Below are some steps on how to:

- Identify Equipment: Identify the equipment or machine to be locked out.

- Pass the Stainless-Steel Cable: Pass the stainless-steel cable to lockout points as required.

- Lock the Mechanism: Lock the cable to stop motion.

- Safety Padlock: Secure it against removal by staff.

- Warning Labels: Install labels in an accessible location to show the lockout status.

Locked, there is access only to authorized staff who possess the key, which provides maximum protection and safety of procedures.

Safety Standards Compliance

Brass cylinder locking cable lockout is international safety standard compliant, i.e., IEC 60947-4-1, and thus effective and reliable. Being standard compliant to such ensures that the product is manufactured on the best quality specifications, and thus the best choice for any company.

Selecting the Best Cable Lockout for Your Business

While selecting a brass cylinder locking cable lockout, remember the following:

- Cable Length: Design it so that it accommodates the equipment on which it will have to be locked.

- Locking Aperture Size: Choose models which are compatible with your safety padlocks.

- Material Strength: Use impact-resistant material for maximum strength.

- Warning Labels: Choose editable models for better safety awareness.

Buying the proper lockout device results in workplace safety and regulatory compliance, finally decreasing the potential for accidents.

Improving Workplace Safety with Cable Lockouts

Lockout/tagout (LOTO) procedures are crucial for minimizing workplace accidents and preventing workers' exposures to sources of energy that are more likely to hurt them. Brass cylinder locking cable lockout remains at the forefront of these programs, offering an effortless, though highly secure, means of lockout of hazardous equipment.

Those organizations that ensure the use of security protocols such as the utilization of lockout/tagout techniques experience fewer work-related incidents, increased efficiency of business operations, and reduced liabilities.

Best Practices to Secure Cable Lockouts

Optimize the performance and longevity of your brass cylinder locking cable lockout by following these best practices:

- Regular Checks: Periodically inspect for wear or damage.

- Training Employees: Appropriately train employees on lockout/tagout procedures.

- Secure Storage Location: Store lockout devices when not being used.

- Replacement When Necessary: Replace broken or worn-out lockout devices.

- Documentation for Compliance: Document lockout procedures for audit.

By adhering to these regulations, companies can provide long-term efficacy for their safety lockout devices.

Other Advantages of Cable Lockouts

Besides workplace safety, brass cylinder locking cable lockouts also possess other advantages that enhance security and efficacy in operation. They provide denial of unauthorized access, and therefore are well-suited to lock off forbidden areas and important assets. They also boost industrial security by providing an additional safeguard to delicate machinery.

With reduced risks and adherence to safety procedures, companies have managed to reduce workplace liability and future legal problems that can be caused by safety infractions. Secondly, such lockouts improve maintenance activities through the access restriction only by competent individuals for sensitive systems. With these benefits, companies have been in a position to make the workplace environment safer and more comfortable.

Applications in Larger Spheres Beyond Workplace Safety

In addition to the prevention of accidental machine start-up, brass cylinder locking cable lockouts provide other security benefits. They may be employed by companies to lock off restricted sections, protect expensive equipment, and increase industrial security.

These units are most suitable in applications where equipment safety is a top priority, for example, construction, utilities, and hazardous materials storage. The fact that they can be fitted with variable cable lengths and multi-language warning labels makes them handy solutions for various applications.

The Bottom Line

A brass cylinder cable lockout is a good investment to lockout hazardous equipment and make workplaces secure with regulatory adherence. Its robustness, elasticity, and ease of use are reasons why businesses that value employees' safety and regulatory adherence will find it a necessary purchase.

Secure your workplace with a brass cylinder locking cable lockout by Bozzys. Get in touch with us today via loto@bozzys.com or call us through +86 15726883657 for world-class lockout solutions that will safeguard your personnel and operations!

2

2