In the industrial sector, the safety of workers and the integrity of operations are paramount. One critical aspect of ensuring this safety is the effective use of lockout/tagout (LOTO) procedures. Among the various equipment used in industrial settings, ball valves are ubiquitous, controlling the flow of liquids and gases in pipelines. Locking out these valves is essential to prevent accidental releases that could endanger lives and disrupt operations. This article delves into the basics of ball valve lockout and emphasizes the significance of equipping employees with proper lockout tools and warning devices to save lives, reduce lost employee time, and cut insurance costs.

Understanding Ball Valve Lockout

What is a Ball Valve lockout?

A ball valve lockout is a type of valve that uses a spherical disc (the ball) to control the flow of substances. The ball has a hole (the bore) through its middle, and when the valve is open, the hole is aligned with the flow, allowing substances to pass through. When the valve is closed, the ball is rotated so that the hole is perpendicular to the flow, blocking the passage. Ball valves are prized for their durability and reliable sealing, making them suitable for a wide range of applications, from water pipelines to chemical processing.

Why Lockout Ball Valves?

Locking out ball valves is critical for several reasons:

- Preventing Accidental Operation: Accidental opening or closing of a valve can lead to hazardous spills, chemical leaks, or gas releases.

- Ensuring Safe Maintenance: Maintenance personnel must be assured that the valve will not be operated while they are working on the system.

- Compliance with Regulations: Many safety regulations mandate the use of lockout/tagout procedures to protect workers from harm.

The Process of Ball Valve Lockout

The lockout process involves several steps to ensure that the valve is securely locked in the desired position (open or closed) and cannot be tampered with. Here’s a general outline:

- Preparation: Identify all energy sources associated with the valve. Inform affected employees about the lockout procedure.

- Shutdown: Turn off the equipment using the valve and relieve any stored energy.

- Isolation: Close the ball valve to stop the flow of substances.

- Application of Lockout Device: Place a lockout device over the ball valve handle to prevent it from being moved. Use a padlock to secure the device.

- Tagout: Attach a tag to the lockout device indicating the reason for the lockout, the person who applied it, and the date.

- Verification: Ensure that the valve is properly locked out by attempting to operate it. Verify that no substances can flow through the valve.

- Maintenance: Perform the necessary maintenance or repair work.

- Removal of Lockout Device: After completing the work, remove the lockout device and padlock, following proper procedures to ensure it is safe to re-energize the system.

Types of Ball Valve Lockouts

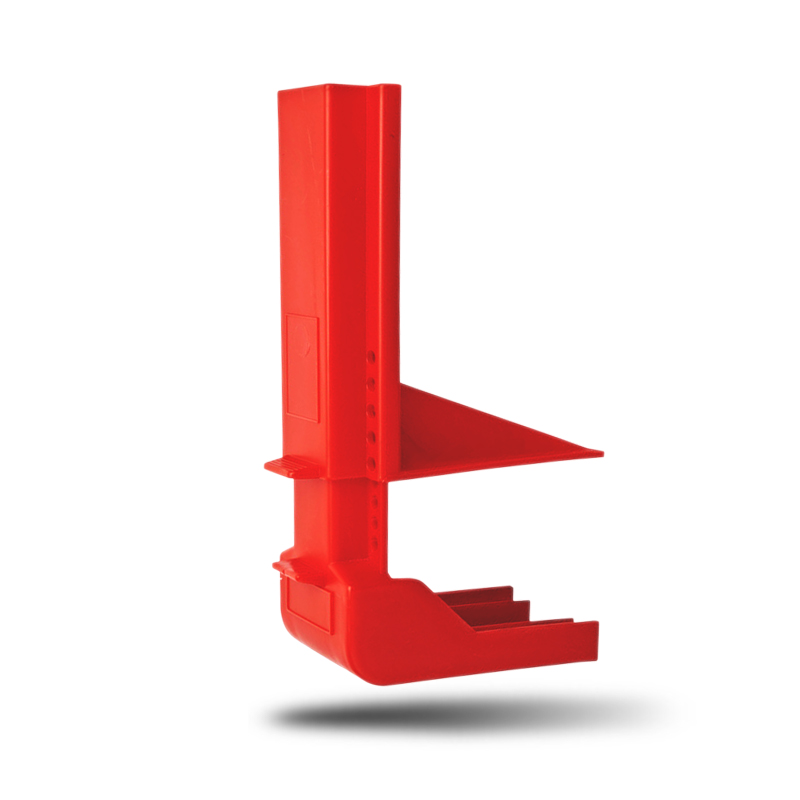

Ball valve lockouts come in various designs to accommodate different types and sizes of valves. For DN70-DN200 ball valves (with diameters ranging from 70mm to 200mm), the following types are commonly used:

- Standard Ball Valve Lockout Devices: These devices fit over the valve handle and prevent it from being turned. They are typically adjustable to fit a range of valve sizes.

- Butterfly Valve Lockout Devices: Specifically designed for butterfly valves, these devices clamp onto the valve handle and restrict its movement.

- Gate Valve Lockout Devices: Used for gate valves, these devices cover the valve handle entirely, preventing access to it.

Equipping Employees with Proper Lockout Tools and Warning Devices

Effective lockout/tagout procedures hinge on the availability of the right tools and warning devices. Properly equipping employees can make a significant difference in maintaining a safe workplace.

Essential Lockout Tools

- Padlocks: High-quality padlocks are fundamental for securing lockout devices. They should be durable, tamper-resistant, and keyed differently or alike, depending on the level of access required.

- Lockout Hasps: These devices allow multiple padlocks to be used on a single lockout point, enabling several workers to lockout the same equipment.

- Valve Lockout Devices: Specific devices designed for ball valves, as well as other types of valves, ensure that they remain locked in the intended position.

- Cable Lockout Devices: These are versatile tools that can secure multiple energy sources, including valves and electrical switches.

- Plug Lockout Devices: These devices secure electrical plugs, preventing them from being inserted into outlets.

- Tagout Tags: Tags provide essential information about the lockout status, including who applied the lock and why. They should be durable and easy to read.

- Signs and Labels: Clear and visible signs around locked-out equipment warn personnel about the lockout status and potential hazards.

- Alarm Systems: Integrating alarm systems that activate when a locked valve is tampered with adds an extra layer of security.

Crucial Warning Devices

Benefits of Proper Lockout/Tagout Practices

Implementing proper lockout/tagout procedures offers numerous benefits, significantly impacting workplace safety and operational efficiency.

Saving Lives

Accidental operation of machinery and equipment can lead to severe injuries or fatalities. By ensuring that ball valves and other equipment are properly locked out, the risk of accidental operation is minimized, protecting workers from harm.

Reducing Lost Employee Time

Workplace accidents can result in significant downtime as investigations are conducted and affected areas are cleaned up or repaired. Proper lockout/tagout procedures minimize the risk of accidents, thereby reducing the amount of lost employee time due to such incidents. Additionally, a safe work environment fosters employee confidence and productivity, leading to less absenteeism and higher morale.

Cutting Insurance Costs

Workplace accidents can lead to higher insurance premiums and increased workers’ compensation claims. By implementing effective lockout/tagout procedures, companies can reduce the frequency and severity of accidents, resulting in lower insurance costs. Insurance companies often recognize the efforts of companies that prioritize safety and may offer discounts or lower rates as a result.

Invest in High-Quality Tools

The importance of ball valve lockout in industrial safety cannot be overstated. Proper lockout/tagout procedures, especially for DN70-DN200 ball valves, are essential for preventing accidental releases, ensuring safe maintenance, and complying with safety regulations. Equipping employees with the right lockout tools and warning devices is a crucial aspect of these procedures. By doing so, companies can create a safer work environment, reduce downtime, and lower insurance costs.

Investing in high-quality lockout tools such as padlocks, valve lockout devices, and tagout tags, along with clear warning signs and alarm systems, can make a significant difference in enhancing workplace safety. The benefits are manifold: lives are saved, employee time is optimized, and financial savings are realized through reduced insurance costs. Ultimately, a commitment to proper lockout/tagout practices reflects a company’s dedication to the well-being of its employees and the efficiency of its operations.

2

2