In industrial settings and workplaces where electrical maintenance is routine, safety devices such as Clamp-On Breaker Lockouts play a crucial role in preventing accidental activation of circuit breakers during repairs or maintenance. These lockouts provide a secure method to ensure that electrical circuits remain inactive until work is completed. This article delves into the features, benefits, and applications of Clamp-On Breaker Lockouts and how they contribute to workplace safety.

Understanding Clamp On Breaker Lockout

A Clamp-On Circuit Breaker Lockout is a safety device specifically designed to secure the handle of a circuit breaker, preventing it from being toggled on accidentally. Locking out circuit breakers is part of the larger Lockout/Tagout (LOTO) safety procedure, which aims to isolate hazardous energy sources and reduce the risk of electrical accidents during equipment maintenance.

These lockouts are versatile and compatible with various circuit breakers, making them suitable for industrial facilities, construction sites, and other environments where electrical maintenance is performed regularly. They are particularly effective on single-pole and multi-pole breakers, thanks to a detachable cleat that expands the device’s applicability.

Key Features of Clamp-On Circuit Breaker Lockout

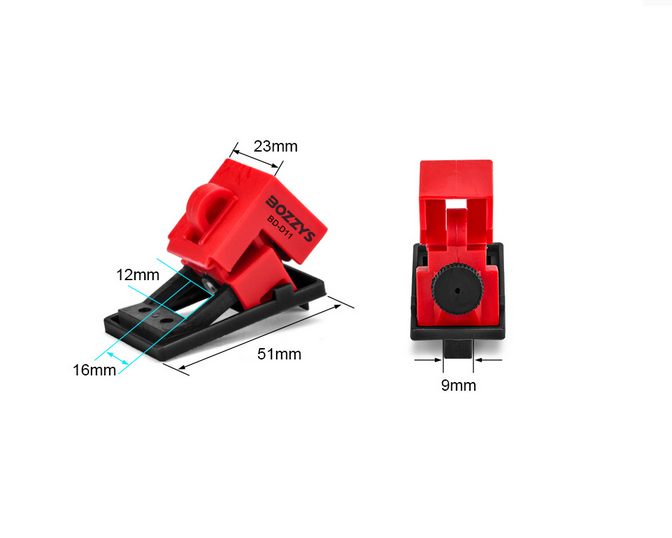

Key features of Clamp-On Circuit Breaker Lockouts include durable materials, tool-free installation, a secure thumbscrew clamp, detachable cleats, and padlock compatibility.

- Material Composition: Clamp-On Circuit Breaker Lockouts are constructed from high-quality materials like polypropylene ABS and PA (polyamide). These materials offer excellent durability, wear resistance, and temperature resilience, making the lockout devices highly reliable in various environments. The reinforced nylon PA material provides additional resistance to wear, corrosion, and high temperatures (operating in ranges from -50℃ to +177℃). This robustness ensures that the lockout devices perform effectively even in harsh industrial conditions.

- Innovative Thumbscrew Mechanism: The thumbscrew clamp design is an innovative feature that allows users to securely fasten the lockout onto the switch tongue with minimal effort. By using a thumbwheel, the clamp tightens around the breaker handle, securely locking it in place. The thumbscrew mechanism makes it easy to install without needing any additional tools, enabling a quick and secure lockout process.

- Enhanced Grip with New Blade Design: The clamp incorporates a new blade design that offers a tighter grip on the circuit breaker handle, reducing the torque required on the thumbscrew. This design provides a more secure lock with less manual force, reducing strain on users and enhancing the reliability of the lockout.

- Detachable Cleats for Extended Compatibility: Each Clamp-On Circuit Breaker Lockout includes a detachable cleat that expands the range of applicable breakers. The cleat ensures compatibility with a variety of single-stage and multi-stage miniature circuit breakers. This versatility makes it a practical choice for facilities with diverse breaker types.

- Padlock Compatibility: The Clamp-On Breaker Lockouts are compatible with padlocks that have a shackle diameter of up to 7mm. This feature allows for the use of standard-sized padlocks, making it easier for facilities to integrate the lockouts into their existing safety systems. The ability to add padlocks ensures that the lockout device is securely locked and cannot be removed without proper authorization.

- User-Friendly Button Buckle Design: The body of the lockout device includes a button buckle design, allowing for easy installation with a simple press of the button. This feature eliminates the need for extra tools and streamlines the lockout process, making it accessible and efficient even in fast-paced environments.

How Clamp-On Circuit Breaker Lockouts Work

The Clamp-On Breaker Lockout operates by clamping over the handle of a circuit breaker, preventing it from being toggled on. Here’s a step-by-step breakdown of the lockout process:

- Positioning the Lockout: The user aligns the Clamp-On Circuit Breaker Lockout over the breaker’s handle.

- Securing the Lockout with the Thumbscrew

- The thumbscrew mechanism is used to clamp the lockout onto the switch tongue securely. The user simply rotates the thumbscrew to achieve a firm hold without needing tools, minimizing installation time.

- Engaging the Cover: Once the clamp is securely in place, the cover is pulled over the clamp to prevent accidental loosening.

- Adding the Padlock: A padlock is inserted through the lockout device, and its shackle diameter (up to 7mm) locks the breaker handle firmly in the off position. The padlock prevents unauthorized removal, ensuring that the lockout remains in place until maintenance is complete.

Advantages of Using Clamp-On Circuit Breaker Lockouts

Clamp-On Circuit Breaker Lockouts enhance workplace safety by preventing accidental circuit activation, ensuring compliance with safety standards, and simplifying maintenance procedures.

- Enhanced Safety: Clamp-On Breaker Lockouts provide a reliable means of preventing accidental activation of circuit breakers during maintenance or repairs. By keeping circuits de-energized, they reduce the risk of electric shocks and other hazards, creating a safer work environment for employees.

- Ease of Use: The thumbscrew and button buckle design allow users to install the lockouts quickly and without tools. This ease of use is particularly valuable in industrial settings where time efficiency is crucial, as it minimizes the time required to secure each breaker.

- Versatility and Compatibility: The lockout’s detachable cleat makes it compatible with a wide range of breaker types, both single and multi-pole. This versatility allows facilities to use a single lockout model for various breaker sizes, simplifying the lockout/tagout inventory.

- Compliance with Safety Standards: Lockout/tagout procedures are mandated by organizations such as OSHA in the United States, which require workplaces to implement safety measures that prevent the accidental release of hazardous energy. Using Clamp-On Breaker Lockouts helps companies stay compliant with these safety regulations.

Applications of Clamp-On Circuit Breaker Lockouts

Clamp-On Breaker Lockouts are widely used in environments where electrical maintenance is frequent and where safety is a priority. Common applications include:

- Industrial Facilities: In manufacturing plants, these lockouts are used to isolate equipment and machinery from their power sources during maintenance.

- Construction Sites: On construction sites, electrical panels often require frequent servicing. Lockouts ensure that circuits remain deactivated until work is safely completed.

- Commercial Buildings: Facility managers in commercial settings use lockouts to prevent accidental energizing of circuits during routine inspections and repairs.

- Energy Sector: Power generation and distribution facilities rely on breaker lockouts for added safety during equipment servicing and grid maintenance activities.

Clamp-On Circuit Breaker Lockouts are essential safety devices that contribute to workplace safety by preventing accidental activation of electrical circuits. Constructed from durable polypropylene ABS and PA materials, these lockouts are designed for ease of use, compatibility, and reliability in various industrial settings. The thumbscrew mechanism, enhanced blade design, and detachable cleat make these lockouts suitable for a wide range of circuit breakers, while the 7mm padlock compatibility ensures secure, authorized access.

By integrating Clamp-On Breaker Lockouts into lockout/tagout procedures, facilities can effectively isolate electrical energy sources, comply with safety regulations, and protect employees from hazardous energy. The importance of these devices in promoting safety and maintaining operational efficiency cannot be overstated, making them a valuable addition to any workplace’s safety toolkit.

2

2