Industrial safety is the most important feature for any business that is dealing with complicated machinery and hazardous environments. That’s where the Sanitary Butterfly Valve Lockout provides an essential part in maintaining valves that can be securely locked to avoid unintended operation during maintenance or servicing. The Butterfly Valve Lockout is designed to work on sanitary butterfly valves and offers an exceptionally solid, adjustable, and very effective solution for equipment lockout. The purpose of this article is to review the operation principle of the Butterfly Valve Lockout, its main features, and why it is indispensable in workplace safety.

What is the Sanitary Butterfly Valve Lockout?

The sanitary butterfly valve lockout is a uniquely designed safety device used to lock out butterfly valves within industries. Butterfly valves are quite common in such industries as food and beverage processing, pharmaceuticals, and chemical plants. These kinds of valves control the flow of liquids, gases, or semi-solids through a pipe by means of a rotating disk.

These Valve Lockouts maintain the valve in the “off” or closed position during maintenance or repair. In this way, it negates the possibility of accidental start-up or energizing of any equipment, which may result in hazardous accidents, injury, and even death. Lockout devices like these are part of an overall lockout/tagout safety program that meets OSHA standards and follows industry best practices.

Sanitary Butterfly Valve Lockout Features

Sanitary Butterfly Valve Lockout is designed basing on a number of key features that make it superior, in relation to the lockout of butterfly valves. These include:

Fits Valves Ranging from 70mm to 210mm

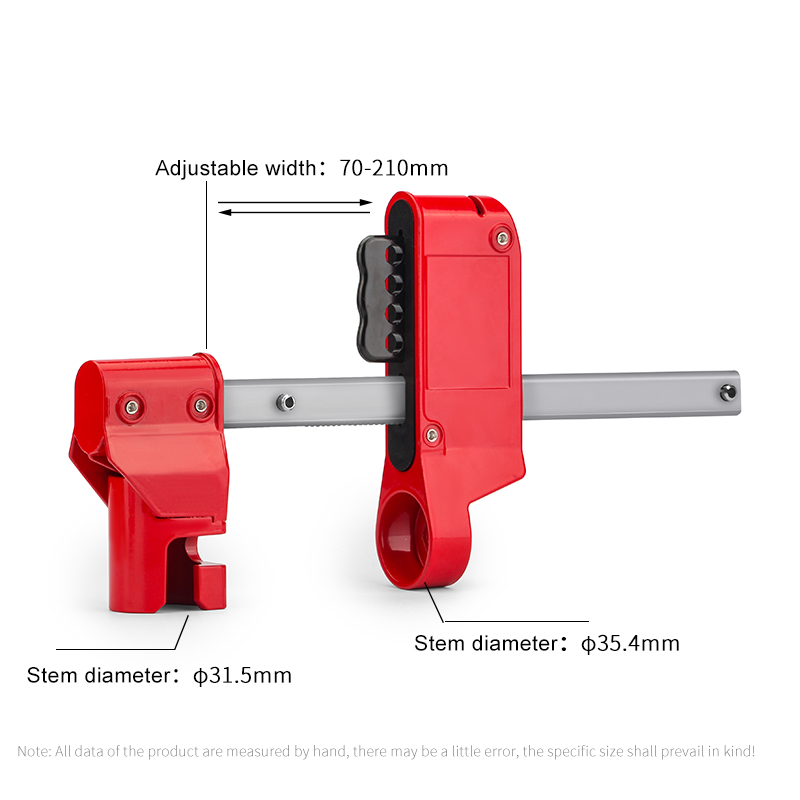

The lockout device is versatile and adjustable for valve sizes ranging from 70mm up to 210mm. This will enable its insertion into various types of butterfly valves, hence a tool that has gained broad flexibility in many industries.

Adjustable Width

This lockout is uniquely designed to accommodate and lock various butterfly valves of different handle lengths with an adjustable width. The adjustment can be done left-right to ensure a good and safe fitting on the valve for fitting and different sizes. This enables valve lockout to suit multiple types of valves without necessarily having several lockout devices.

Four Locking Holes for Maximum Safety

The Valve Lockout has four locking holes for attaching up to four padlocks at once. This is very effective when several workers are servicing the same piece of equipment. Each worker can attach his lock so that the valve cannot be operated until all the locks are removed. In this respect, the multi-lock function ensures that all persons working on the valve are counted for and the equipment is safely locked out.

Durable Construction

Indeed, the Butterfly Valve Lockout is manufactured from tough combinations of aluminum and hardened thermoplastic materials to stand up in difficult industrial environments. The lockout device will not rust or corrode indoors or outdoors under extreme temperature fluctuations or harsh chemicals, ensuring a long performance in the most extreme conditions.

Workable with Steel Padlocks and Safety Signs

For maximum safety, the butterfly valve lockout is designed to fit its function along with steel padlocks and safety signs. That locks up the valve tightly but as well serves as a warning that it is locked out and must not be operated. These extra safety precautions when using the lockout after use avert accidents and will keep in tune with the industrial safety regulations.

How the Sanitary Butterfly Valve Lockout Works

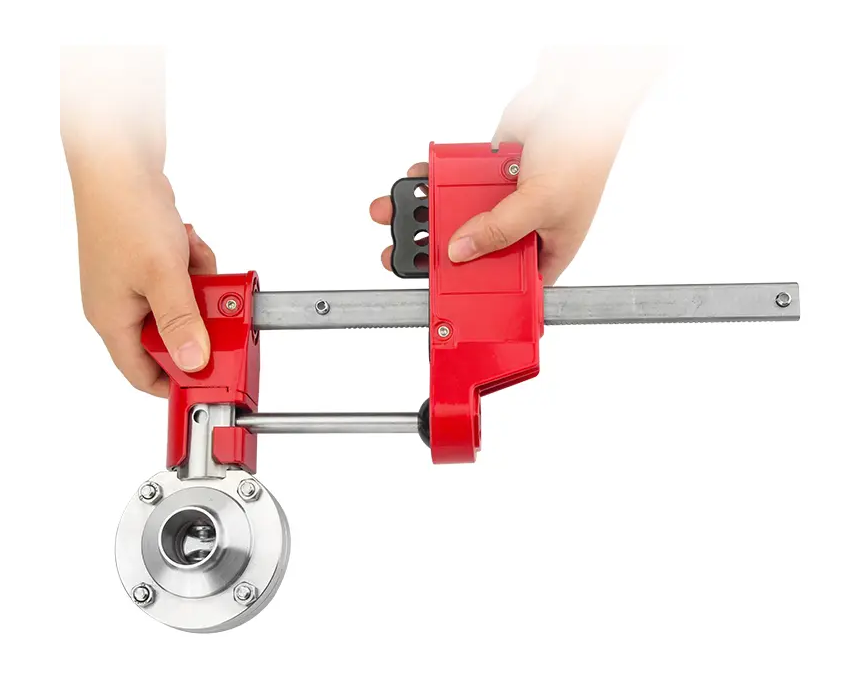

The use of a Sanitary Butterfly Valve Lockout is simple, easy, yet effective. It fits over the handle of the butterfly valve and prevents the handle from being turned and the valve opened. Once the lockout device is fitted in place, padlocks are added through the locking holes to hold the device in position.

The major characteristic of this device is that it can allow up to four padlocks. It means in the case of several workers’ participation in servicing, each one may apply their own padlock. The restart of the equipment cannot be carried out before all padlocks are removed; therefore, nobody will be exposed to hazards in the case when work is still carried out.

The lockout device comes with an adjustable width to fit different length handles of butterfly valves, hence pretty versatile in many applications. The prevention of accidental valve operation significantly reduces the possibility of injury or equipment damage during maintenance operations with this Valve Lockout.

Why the Sanitary Butterfly Valve Lockout is Critical in Workplace Safety

1. To avoid the occurrence of accidental valve operations

The most obvious advantage of using a Sanitary Butterfly Valve Lockout is that it doesn’t allow accidental operation of the valve. Butterfly valves work to regulate the flow of some probably dangerous materials, and accidental opening can cause a spill, leak, or release of some hazardous materials. By locking the valve, you negate the risk of its unintentional operation, hence protecting workers and the environment.

2. Supports OSHA Compliance

Whenever an industry involves machinery and equipment operation that could be hazardous to the employees, OSHA requires the implementation of lockout/tagout practices for employee protection. Sanitary Butterfly Valve Lockout is a very important solution to their needs, working with and assisting companies in meeting the criteria of OSHA and staying away from costly fines or possible litigation.

3. Improves Efficiency in Maintenance

Lockout/tagout procedures are not only essential to safety but also to efficiency in the process of maintenance and repair. When personnel can be assured that machinery or equipment is positively locked out, they will do their work with assurance, knowing they are safeguarded against unexpected occurrence. Thus, the work gets accomplished faster and in a more efficient manner than when personnel are worrying about an accident; this helps reduce any lost time and assures that production remains on schedule.

4. Cost-Effective Safety Solution

One other cost-effective avenue to improve workplace safety is through an investment in Valve Lockout. This is because making a lockout device requires the use of durable materials that can put up with tough conditions for quite a period of time. Thus, it forms a great investment for any business venture that desires to protect its workers and equipment.

5. Versatility Across Industries

The Valve Lockout finds its applications across industries, right from food and beverage processing to pharmaceuticals, chemicals, and manufacturing. In addition to its versatility for use on different valve sizes and handle lengths, it proves to be one of the most important tools to deploy for a variety of uses.

Conclusion: Let Safety Come First with Sanitary Butterfly Valve Lockout

Safety should never be compromised in any industrial field. The Valve Lockout offers a sure and efficient way to lock out butterfly valves so as to prevent accidental operation and thereby protect the work from possible injuries. Constructed with durable material, this lockout is designed to be adjusted and house up to three padlocks for its locks, making it an indispensable tool in any lockout/tagout program.

A Sanitary Butterfly Valve Lockout will help your company stay current on the necessary safety issues and create a much safer, more productive workplace. This device is one you need in the manufacturing environment, be it food processing or chemical production, for workers’ safety and equipment security.

2

2