Safety is always of primary importance in any workplace setting. Lockout/tagout (LOTO) processes prevent accidents by preventing equipment and machinery operation during maintenance. Cable lockout for cabinet door is among the equipment required in such processes. Security and ease are the advantages of this device, providing an ordinary method of restricting cabinet access to unauthorized employees, safeguarding workers and machines as well.

What is a Cabinet Door Cable Lockout?

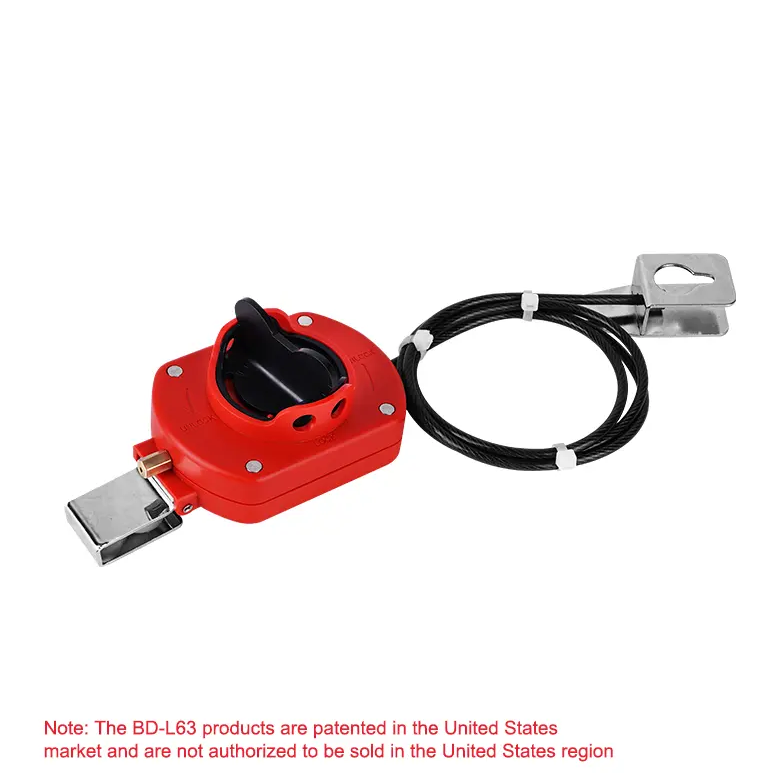

Cable lockout of cabinet doors is a light yet extremely robust safety device designed to restrict access to cabinets holding crucial electrical or mechanical parts. It consists of 1-meter long stainless-steel cable covered with long-lasting and resistant UV-resistant PVC. The lockout body consists of impact-resistant, non-conductive nylon ABS material that qualifies it as an excellent choice for most industrial applications. Once tightened, the cable can be left but not touched or removed. The lock holes have dimensions of 6mm and 8mm to fit most safety padlocks.

Key Features of Cable Lockout for Cabinet Door

The following are the key features to look out for:

- Weather and Durable: This stainless-steel core with UV-resistant PVC outer coating makes the product last for long periods of harsh weather conditions.

- Adjustable Cable Length: This system offers adjustable cable length which extends to one meter as its basic standard to match different security specifications for cabinets.

- Space-Saving and Portable: For convenient storage along with machinery or equipment, without unnecessary wastage of space and in an effort to ensure efficiency.

- Universal Fit: For every safety padlock size, as an effort towards ensuring flexibility within any working environment.

- Visible Warning Labels: With warning labels that can be adjustable in different languages in order to allow company branding and safety notification.

Applications of Cable Lockout for Cabinet Door

Cable lockout for cabinet door is widely utilized in organizations to secure equipment and protect against misuse. It finds wide application in factory plants, electric panels, warehouses, laboratories, and residential protection.

These lockout tools find the majority of applications in factories where dangerous equipment is required to be serviced every so often. Cable lockouts are utilized by companies to prevent the machines from being started inadvertently and to maintain the workers performing the maintenance safe. Utility and electrical companies ensure that it becomes easy for them to use these devices to lock up high-voltage cabinets against low electrical risk. Cable lockouts find their applications in hospitals and laboratories to lock cabinets of delicate chemicals and machinery from misuse or mishandling.

Why Cable Lockout for Cabinet Door?

A cabinet door cable lockout is an important component of workplace safety. It reduces injury, protects equipment from tampering, enhances safety regulation compliance, and reduces operation disruption by preventing misuse.

The majority of the companies are saddled with unauthorized staff accessing the equipment, which may lead to possible accidents or equipment damage. Cable lockout avoids such hazards from arising. Full lockout/tagout (LOTO) programs employed by companies effectively reduce workplace injuries, providing a secure working environment for workers.

How to Install a Cable Lockout for Cabinet Door?

It is easy to install a cable lockout for cabinet door. Simply follow these steps:

- Identify the Cabinet or Equipment: Determine which cabinet or equipment has to be isolated.

- Wrap the Cable: Insert the stainless-steel cable into the locking points of the cabinet door.

- Secure the Locking Device: Lock the cable and insert the lock into the matching locking holes (6mm or 8mm).

- Use a Safety Padlock: Lock the lockout device with an appropriate padlock.

- Attach Warning Signs: Make the warning labels conspicuous and clearly show the restriction.

Once it is locked, only the authorized individuals who have the key can open it, thereby ensuring maximum security.

Adherence to Safety Specifications

Cable lockout cabinet door complies with industry standards for safety, providing consistency and effectiveness in procedures for workplace safety. It has been certified as per IEC 60947-4-1, a global standard for the safety and performance of electric equipment. Complying with the standard verifies that the lockout device possesses high levels of design standards, and thus it can be applied in various kinds of industrial and commercial settings.

Choosing the Appropriate Cable Lockout For Your Application

When selecting cable lockout on a cabinet door, keep in mind cable length, diameter of locking aperture, material's lifespan, and warning label legibility. In an organization where there is highly sensitive equipment, the organizations should select lengths of the adjustable cable for certain sizes of cabinets that will suit well.

The Roles of Cable Lockouts in Secure Working Conditions

Secure working conditions are important to companies, and lockout/tagout equipment serves vital functions in ensuring secure working conditions. Cabinet door cable lockout is an inexpensive but useful safety device that serves functions in accident prevention and compliance with regulations. Companies that invest in quality lockout equipment have a responsibility towards safe working and operation efficiency. It would be necessary if all businesses could consider cable lockouts at their workplaces to help tighten security.

Maintenance and Best Practices for Cable Lockouts

Maintenance and proper care are necessary to make a cable lockout for cabinet door effective. Companies must adopt these best practices:

- Regular Inspections: Regularly inspect the cable lockout for wear, including damaged cables or compromised locking mechanisms.

- Employee Training: Train employees on the significance of lockout/tagout (LOTO) procedures and correct use of cable lockout devices. Consider refresher courses to ensure they understand how to use these lockouts well.

- Accommodating Storage: Store lockout devices at assigned locations to avoid damage or loss.

- Replacement Change at Once: Replace damaged or worn-out cable lockouts to maintain safety equipment.

- Compliance and Recording: Document lockout procedures to ensure compliance with safety standards.

Following these maintenance recommendations will allow companies to provide the highest life expectancy to their cable lockout gear and workplace safety in general.

A cabinet door cable lockout is a safety-critical piece of equipment for laboratorial workplace safety, prevention of unauthorized access, and safety standards compliance. It is rugged, adjustable, and simple with its design and can be used in industrial, business, or domestic applications.

Secure your workplace with a steadfast cable lockout for cabinet door. Order from Bozzys today and increase safety today!

2

2